Fire fighting station design

Fire pumps are mounted on a special metal frame, which allows for quick and convenient transportation of the entire station, its building and installation at the facility. Both the main and standby pumps (if provided for in the project) and the electric pressure maintenance pump can be mounted on the same structure.

Conditions of the implementation of the EN 12845 fire fighting station standard

Fire pumps must be installed in a room dedicated to this purpose, in a room that provides at least 60 minutes of fire protection. This can be a separate building, a building connected to the main building protected by fire sprinklers, or a separate room in a building protected by fire sprinklers. These rooms also have requirements for ambient temperature. If the installed fire pumps are driven by an electric motor, the ambient temperature in the room should not be lower than 4 °C, while if the pump is driven by a diesel engine, it is necessary to ensure a temperature of at least 10 °C. The room must also be adequately ventilated, which is especially relevant if fire pumps with a diesel engine are provided. The requirements that must be implemented to achieve proper ventilation of the room are provided by the fire fighting station manufacturer.

The requirement for the temperature of the water pumped by the fire fighting station is no more than 40 degrees Celsius. If a submersible pump is used, the water temperature is limited to 25 degrees, except in cases where the submersible pump is manufactured in accordance with the provisions of another standard (EN 122589-12) and is adapted to work with temperatures up to 40 degrees.

Shut-off valves must be provided in the fire fighting station installation on both the pressure and suction sides.

In order to ensure smooth water suction, it is important to follow the rules of positioning fire pumps. If a tank is used for water supply, at least 2/3 of it should be above the central axis of the pump. Also, this axis must be no lower than 2 meters above the lowest water point in the tank. Each fire pump must always be filled with water, and a separate, dedicated water tank is used for this task, the water level of which is maintained by a separate electric pressure maintenance pump.

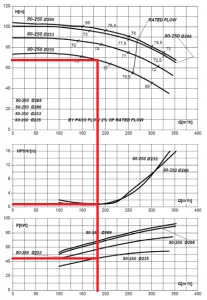

Pressure sensors are responsible for the automatic start of the fire fighting station, which, having sensed a pressure drop in the system, automatically start the fire pump. The pipe to which the pressure sensor is connected should be at least 15 mm in diameter. If the fire fighting station consists of 2 separate pumps, the first pump automatically starts when the pressure in the system drops to 0.8*P, where P = system pressure with closed valves. The second pump starts when the pressure value drops to 0.6*P. The pumps operate until they are physically, manually switched off.

The power supply to the fire fighting station must be provided by a separate line, all cables must be resistant to fire and mechanical damage. The safety relays must withstand the increased load that occurs during engine start-up for at least 20 seconds.